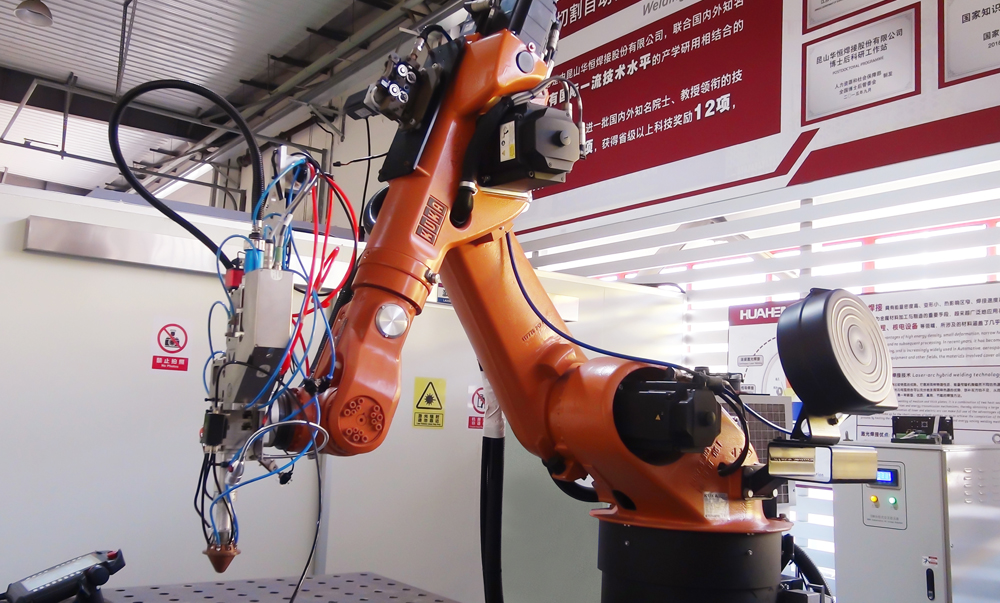

The KUKA KR16 robot consists of a KR6 robot body with a toggle structure, a KRC2 control cabinet, and a teaching controller KCP; the dynamic model optimization of the aluminum alloy robot body and the high-speed motion curve makes the acceleration performance of the KUKA robot better than other ordinary robots. It is 25% higher, which is beneficial to improve the system life and optimize the working cycle.

KR16 Robot

Versatile and flexible application

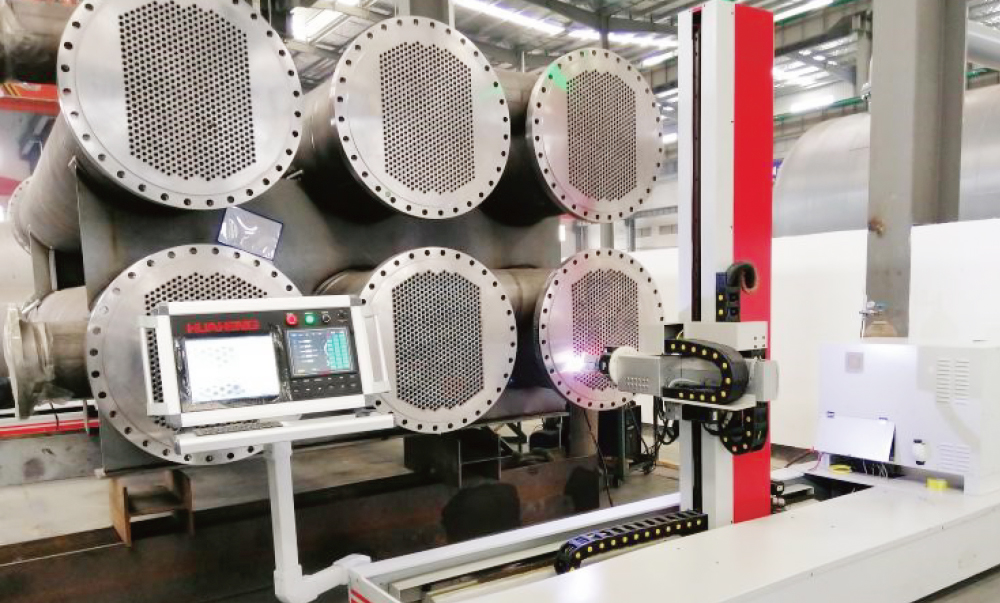

Suitable for most applications in the process industry

Structure | Vertical polyarticulated shape (6 degrees of freedom) | |

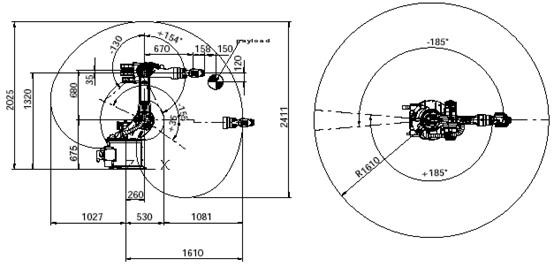

Single axis max range of motion | Axis 1 (Ground) | ±185° |

Axis 2 (upper arm) | +35°,-155° | |

Axis 3 (lower arm) | +154°,-130° | |

Axis 4 (Wrist Rotation) | ±350° | |

Axis 5 (wrist swing) | ±130° | |

Axis 6 (wrist rotation) | ±350° | |

Single axis max Movement speed | Axis1 | 156° /s |

Axis2 | 156° /s | |

Axis3 | 156° /s | |

Axis4 | 330° /s | |

Axis5 | 330° /s | |

Axis6 | 615° /s | |

Working radius | 1610 mm | |

Repeatability | ±0.1mm | |

load mass | Axis 6 maximum load 16 kg | |

Installed capacity | 6 kW | |

Weight | 235 kg | |

Installation method | Upright/upside down | |

Protection class | IP54 | |

| For detailed technical parameters, please refer to the technical diagram | ||

中文

中文