Applicable wall thickness: 5-90mm

Applicable materials: carbon steel, alloy steel, stainless steel, low temperature steel, duplex stainless steel

Groove type: U, X, V, double V

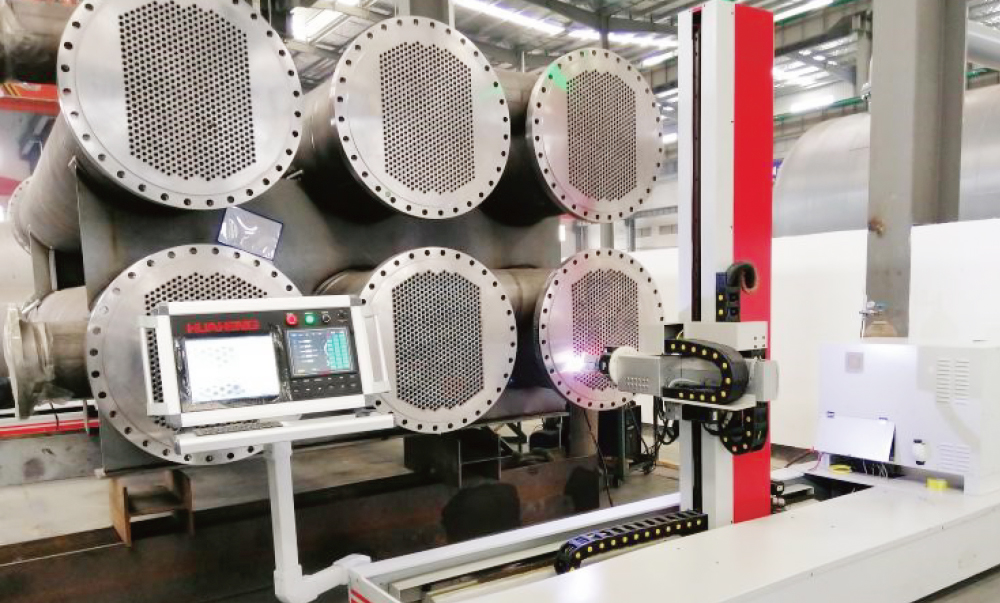

External groove + internal boring integrated CNC machining (PCEBM-24)

Bevel angle: 0-45° adjustable

Feeding method: radial automatic differential feed or axial CNC electric feed

Retraction method: radial automatic electric tool retraction or axial CNC electric tool retraction

Drive mode: driven by motor + reducer

Spindle speed: 0-133r/min stepless adjust/stepless frequency control (EBM-24); 0-156r/min (PCEBM-24)

Axial displacement: 150mm (spindle/main spindle), 300 mm (head h/eadstock)

Lateral displacement: ±100mm

Control system: PLC control, 7-inch color touch screen, man-machine dialogue mode I

Technical indicators | Applicable pipe diameter | CNC feed | Groove realization method | Tool path | Programming interface | Speed mode | Whether rigid cutting | Mechanism for improving reproducibility of centering clamping | ||

PCEBM-24 | DN60-600 | Full CNC | 1 knife to achieve, different grooves | Programming continuous passes,One-click cutting | Graphical+to parameterize | Frequency conversion + variable wheel speed regulation | Yes | Rack and pinion centering, high reproducibility | ||

EBM-24 | DN100-600 | Semi CNC | Multiple knives different grooves | Manual multiple feed | Graphical + parametric, less variety | Gearbox speed regulation | No | Positive and negative thread screw alignment,low reproducibility | ||

EBM-16 | DN30-400 | Button Control | Multiple knives different grooves | Manual multiple feed | No programming | Gearbox speed regulation | No | Positive and negative thread screw alignment,low reproducibility |

中文

中文