A number of technical indicators have reached the international advanced level

Thickness up to 100mm

Bevel efficiency: ≤5 minutes (DN200 SCH40)

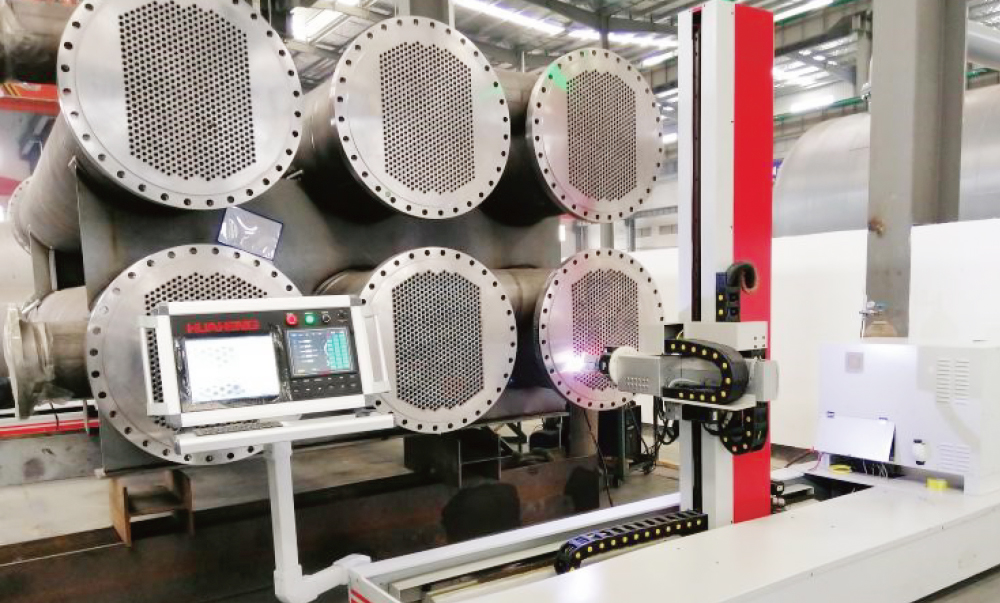

Advanced full CNC three-axis patented technology feed mode: three-axis linkage, axial + radial two-axis servo feed, feed adjustment as needed

The first in the industry to solve the integrated programmatic automatic CNC bevel processing of external groove + internal boring

The programming method of graphical parameter input can get rid of the need for workers' CNC programming operation skills

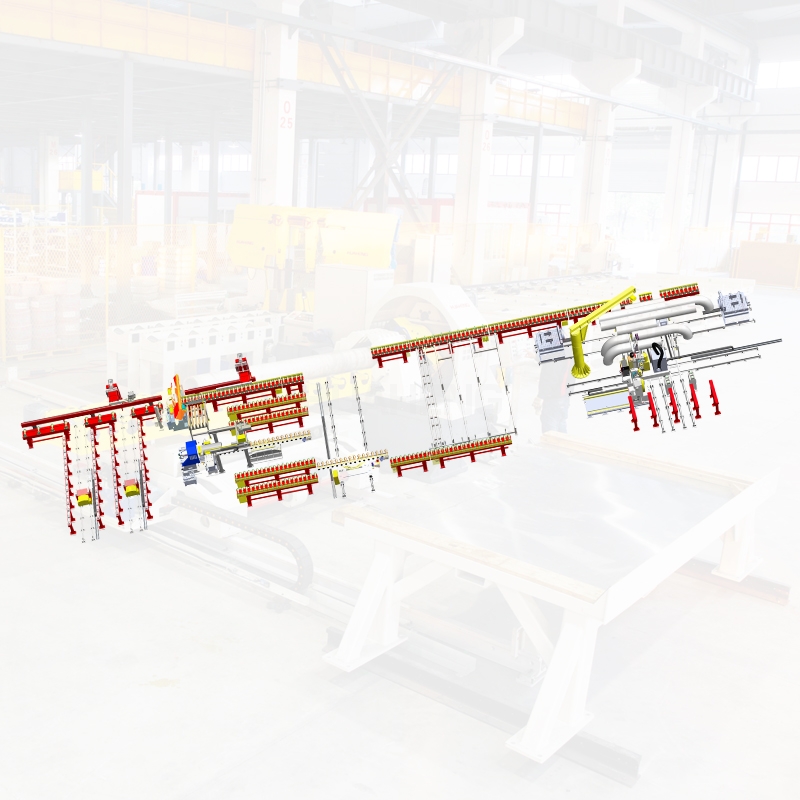

Design of 5-axis RGV logistics trolley (walking, jacking, reloading, rolling, unloading) and automatic logistics transfer

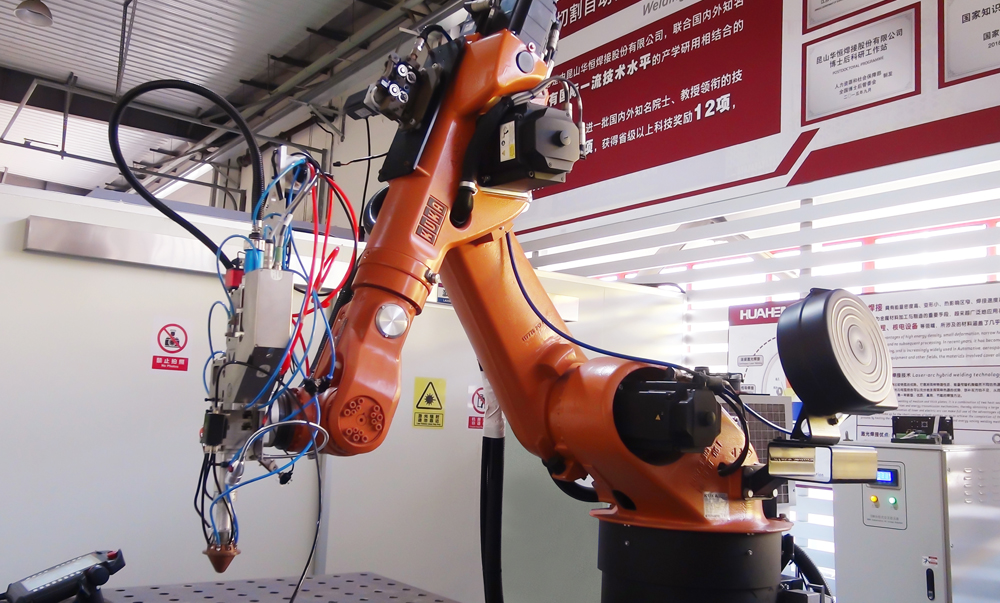

It can realize U-shaped, double-V, V-shaped and advanced technology composite groove integrated CNC automatic processing method, and the processing process does not change

Rigid cutting

Model | CBL-24 CBL-32 |

Bevel form | U, V, double V, internal boring, and external groove + internal boring integrated CNC machining |

Number of tools | Up to 2 (no tool change required for internal boring) |

Blade | Finished carbide inserts |

Blade life | Long (≥50 mouths) |

Cutting speed | 3 minutes/mouth(DN200x12) |

Cutting function | Automatic chip removal |

Pipe diameter bevel range | 4-24"(Φ108-630mm) 8-32"(Φ219-850mm) |

中文

中文