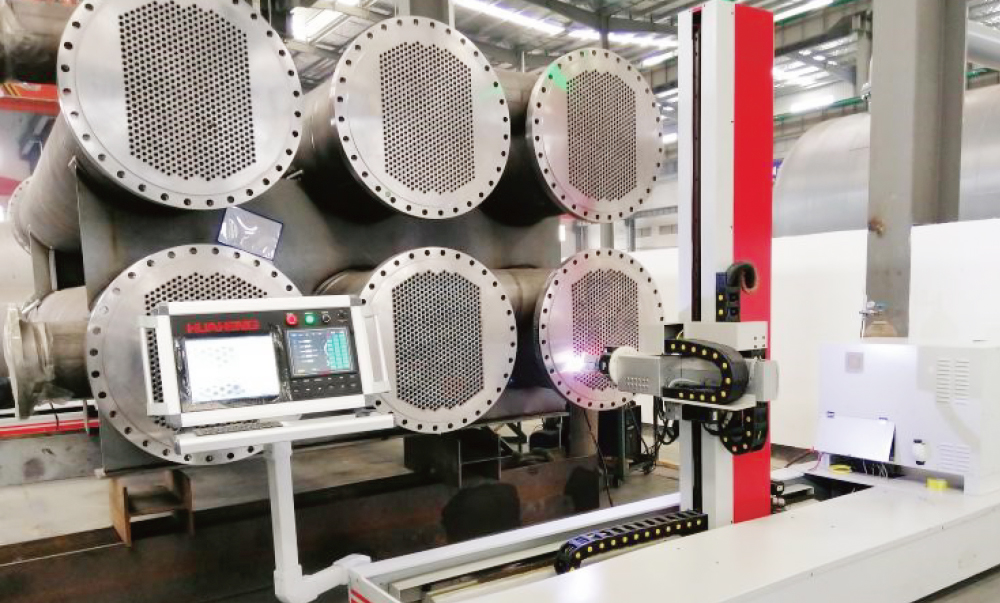

The system is specially designed for pipe to pipe butt joint TIG orbital welding, and the welding range could reach Φ300mm and above.

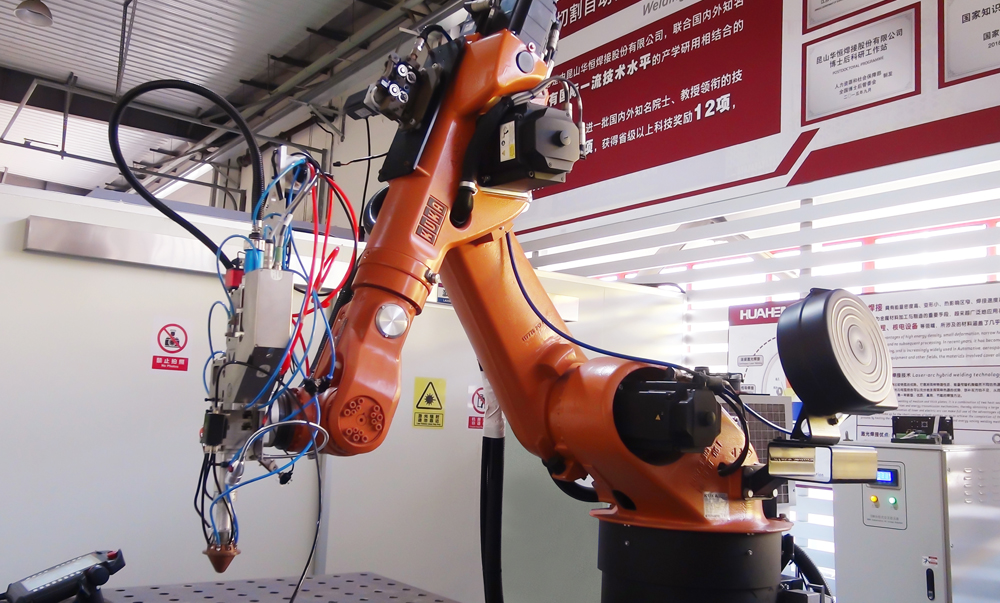

Cold wire/hot wire TIG DC/pulse all-position automatic welding crawling trolley for large diameter pipe and pipe;

Pipes with different diameters are equipped with different positioning guide rings, and the guide rings are driven by rack and pinion;

Self-contained integrated wire feeder realizes unwinding wire feeding;

Automatic arc length tracking, yaw cover function;

The efficiency of hot wire welding is 3~5 times higher than that of cold wire welding;

The groove form of the workpiece can be V-shaped or U-shaped;

Suitable for welding carbon steel, stainless steel, duplex steel and other alloy materials;

Pipe diameter range(mm) | 304.8~609.6 (12“~24”) |

Wall thickness mm | 3~20 |

Welding speed mm/min | 60~180 |

Cold wire feeding speed mm/min | 95~1500 |

Hot wire feeding speed mm/min | 360~5500 |

Wire diameter mm | 1.0/1.2 |

Arc length height mm | 0~40 |

Yaw width mm | 0~40 |

中文

中文